Categories

PUR Twisted Pair Shielded Cables

STANDARD USE

Twisted pair shielded control cables for dynamic applications in industrial drag chains, with small external dimensions, high flexibility and outstanding resistance to industrial oils and other chemical and mechanical agents, UL-CSA approval.

Data sheet More infoTechnical details:

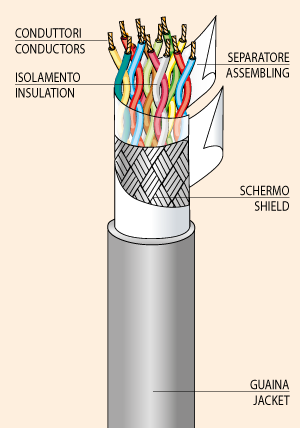

Conductors

Extraflexible stranded bare copper (Cu-ETP1)CEI 20-29 cl.6, VDE 0295 cl.6, EN 60228, IEC 60228 ref.

Cross sect. area (mm2): from 0,14 to 0,50.

Insulation

Polyolefin (PE, PP) UL 1581 ref.Colour code: DIN 47100

Assembling

Protective tapeOverall Shield

Tinned copper braid.Optical coverage: ≥ 85%

Optional Assembling

Non woven tapeJacket

Low friction halogen free matt flame retardant Polyurethane, hydrolysis, microbial attack, abrasion, tear, oil resistantUL 1581 ref.

Colour code:

Grey Ral 7001 (other colours on request)

Operating Voltage

300 VTest Voltage

2000 VOperating Temperature

Dynamic application: -40°C +80°CBending radius

7,5 times overall diameter of cable.Maximun Speed

240 m/minMaximun Acceleration

30 m/sec2Flex Life

from 3 to 6 million of motions(bending radius 10 times overall diameter of cable)

Flame retardant test

CEI 20-35/1-2, EN 60332-1-2, IEC 60332-1-2, UL cable flame test, FT1 testNon-Halogen Verification

< 0,5 % (CEI 20-37/2-1, CEI EN 50267-2-1, IEC 60754-1)UL-CSA Approval (E235078)

AWM STYLE 20233 o 20549 – CSA I/II A/B 80°C 300 V FT1| CODICE / CODE | FORMAZIONE / TYPE | Ø ESTERNO / OUTER Ø ±5% (mm) | PESO MEDIO / AVERAGE WEIGHT (kg/km) |

|---|---|---|---|

| 2x2x0,14 | 5,1 | 33 | |

| 3x2x0,14 | 5,3 | 35 | |

| 4x2x0,14 | 5,8 | 41 | |

| 5x2x0,14 | 6,2 | 47 | |

| 6x2x0,14 | 6,8 | 58 | |

| 8x2x0,14 | 8,1 | 78 | |

| 10x2x0,14 | 8,3 | 83 | |

| 16x2x0,14 | 9,5 | 112 | |

| 2x2x0,25 | 5,8 | 43 | |

| 3x2x0,25 | 6,2 | 46 | |

| 4x2x0,25 | 7,1 | 58 | |

| 5x2x0,25 | 7,3 | 70 | |

| 6x2x0,25 | 8,1 | 80 | |

| 8x2x0,25 | 9,5 | 124 | |

| 10x2x0,25 | 10,2 | 133 | |

| 16x2x0,25 | 12,1 | 186 | |

| 2x2x0,34 | 6,2 | 50 | |

| 3x2x0,34 | 6,5 | 55 | |

| 4x2x0,34 | 7,5 | 72 | |

| 5x2x0,34 | 7,7 | 79 | |

| 6x2x0,34 | 8,4 | 98 | |

| 8x2x0,34 | 10,1 | 145 | |

| 10x2x0,34 | 10,7 | 150 | |

| 16x2x0,34 | 12,2 | 217 | |

| 2x2x0,50 | 6,9 | 59 | |

| 3x2x0,50 | 7,8 | 79 | |

| 4x2x0,50 | 8,2 | 102 | |

| 5x2x0,50 | 9,2 | 116 | |

| 6x2x0,50 | 9,8 | 142 | |

| 8x2x0,50 | 11,5 | 179 |